Food Contact Materials

Where food safety and performance meet.

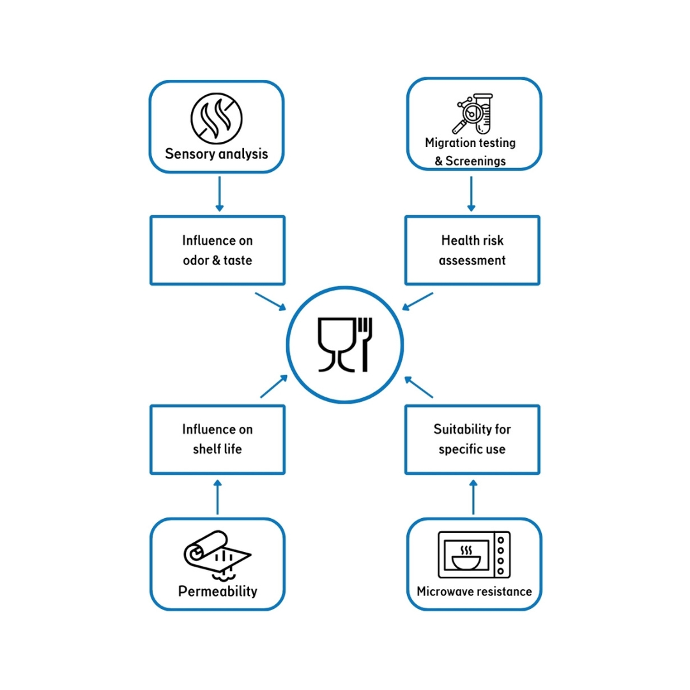

What we do:

Food Contact Materials and articles can exist from different materials, like plastic, cardboard, inks and adhesives, metals and many more.

It's not only packaging but the broad range of materials and articles that comes into contact with foods between its harvesting to its consumption, like kitchenware or food processing equipment.

Food contact materials need to comply with EU rules regarding safety for contact with food and fulfill technical expectations in terms of optimizing our foods shelf life.

The FCM department at IBE-BVI provides analytical services and advice to demonstrate compliance with the EU Regulation for food contact materials and characterization tests like permeability of gasses trough a material.

Food Contact Materials

What are Food Contact Materials?

Our food and drinks often come in packaging or containers, for example kitchen equipment, cutlery and dishes. These are considered as food contact materials.

It's essential to test these materials to trace potential dangerous chemicals which could migrate into the food and drinks we consume.

In Europe, all FCMs must be manufactured following the EU regulations, which ensure that any potential transfer of chemicals to foodstuffs won't put in danger the citizens.

Compliance Testing

Compliance Testing

Packaging and materials intended to come into direct contact with foods must meet the different requirements with regards to food safety. The materials and articles may not transfer their constituents to the food in quantities which could endanger the human health and/or change the composition of the food in an unacceptable way or cause a deterioration in the color, taste or smell of the food.

Migration

Migration tests are used to measure the level of inertness of a material. Measuring migration is essential to prove that materials do not transfer their constituents to the food in quantities which could endanger the human and/or change the composition of the food in an unacceptable way.

Non-targeted screening

This test

allows the detection and identification of (semi)Volatile Organic Compounds

(VOC), such as non-intentionally added substances (NIAS) in food contact

materials packaging. The test can be performed on the material or on the

extracts or food simulants.

Sensory analysis

These tests aim to check that materials do not influence the taste and smell of foods.

After a test set up based on the protocol of L. Robinson and EN 1230, the evaluation is one by a panel test (triangle test).

Gas Permeability

Gas Permeability

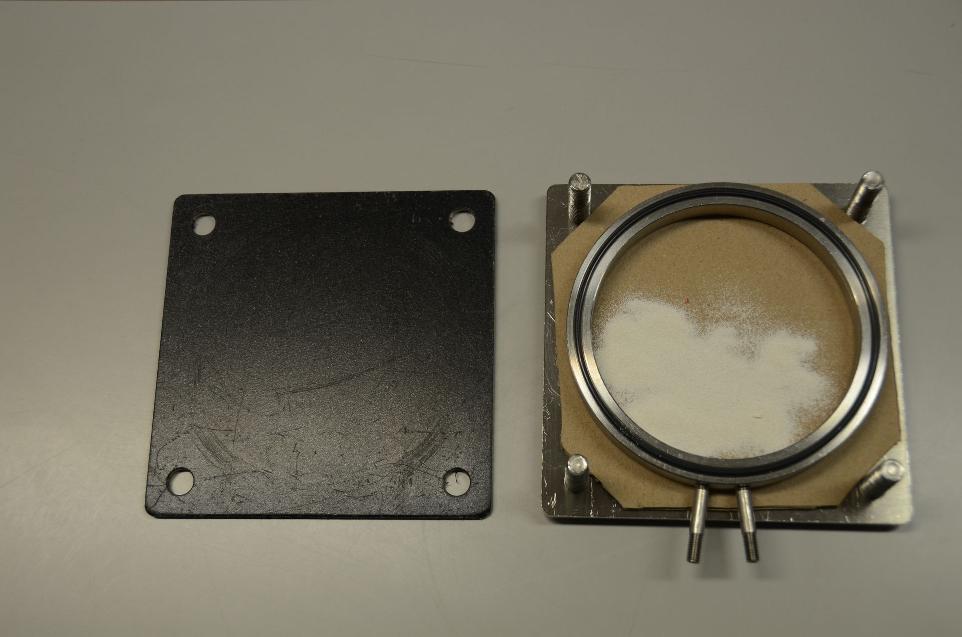

The permeability of gasses (O2, N2, water vapor...) through packaging materials (plastic, films) has an influence on the overall shelf life of food and on the quality of the package products. The testing of these packaging materials is necessary to give insight in these properties. IBE-BVI has several instruments to determine the gas permeability of materials, films and packaging. Based on the tests results an optimal material choice for a packaging can be made.

Water vapor transmission rate (WVTR)

The water vapor permeability of flat materials and small packages can be measured at IBE-BVI by a Mocon PERMATRAN-W 3/34H. This instrument is intended to measure low to high level barriers, using an infrared sensor, at a given test temperature and a given relative humidity. This is performed according to ASTM F1249.

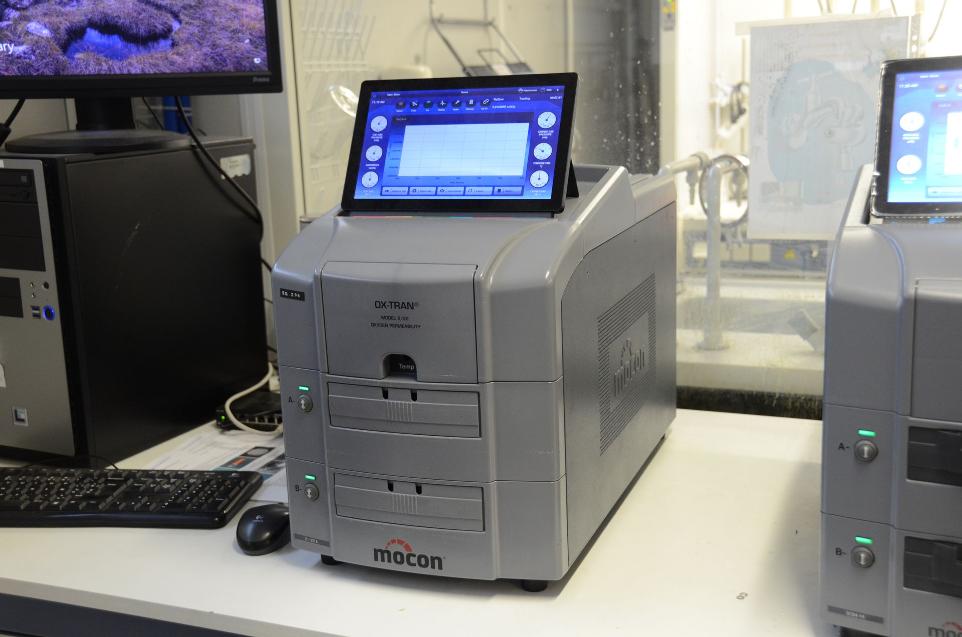

Oxygen transmission rate (OTR)

To measure oxygen permeability of flat materials and small packages, IBE-BVI uses a Mocon OX-TRAN 2/22L. This device measures the OTR by means of a coulometric sensor at a given test temperature and given relative humidity. This can be performed according to ASTM D3985, ASTM F1927 and ASTM F1307.

Q&A

Q&A

The use of recycled plastic for food contact applications is regulated within the EU by regulation EU n° 2022/1616. This regulation provides guidelines for recyclers and converters. More information about this can be found at op Plastic Recycling - European Commission (europa.eu)

Another possibility is the use of recycled material in multi-layer food contact materials, behind a functional barrier, in accordance with art. 13 and 14 of Regulation EU n° 10/2011.

The definition of food contact materials (Regulation EC n° 1935/2004) also includes materials and articles, which in their finished state can reasonably be expected to be brought into contact with food or to transfer their constituents to food under normal or foreseeable conditions of use.

Food contact is defined by the Council of Europe Resolution CM/Res (2020)9 as direct (physical) contact or indirect (through the gas phase or through different packaging components or layers in a multi-layer material) contact of a food contact material or article with a food.

So, it is a case by case evaluation, depending of possibility of substances to transfer through the primary packaging of air to the food.

All food contact materials must comply with EC 1935/2004 and EC 2023/2006. In Belgium, the Royal Decree 11/05/1992 (and amendments) also applies to all food contact materials.

For plastics, Regulation EU 10/2011 (and amendments) applies.

For other material types you can refer to Resolutions or Policy statements of the Council of Europe (CoE) or national laws/recommendations.

National legislation is in place in the majority of EU Member States, but these may differ from one Member State to another. The European Commission's Joint Research Centre (JRC) published a study in 2017, including an overview of the national measures in force at that time.

In order to define the suitable test set-up, following information is needed:

- What is the material that the product is composed of: plastic (polymer type(s) / paper and board (coated or uncoated), multi-material, …

- For which types of foodstuffs is the product/packaging intended (aqueous, acid, fatty, …)?

- What are the foreseeable conditions of use (time and temperature) of the product/packaging?

- Is the product/packaging intended for single use or for repeated contact with foodstuffs?

- Are there substances used in the manufacturing of the materials that are subjected to a specific migration limit or other restrictions?

It is not obliged to do migration tests with all simulants that are included in the EU Regulation n° 10/2011. If a verification of the migration limit is done for simulant A (10% ethanol), simulant B (3% acetic acid) and simulant D2 (vegetable oil), compliance for contact with all kinds of foods is demonstrated. These three simulants cover the major possible physic-chemical characteristics of food: namely the hydrophilic, the lipophilic and the acidic character.

No validity date is mentioned in the regulations EU/1935/2004 or EU/10/2011 for the DoC and its supporting documentation. So, the DoC and migration tests remain valid as long as the applicable legislation is not altered and the material/production method that is the subject of the DoC is not changed.

Though, EU members states can have additional requirements for food contact materials. These national measures may contain validity terms for DoC and supporting documentation such as migration reports. For instance, the Belgian Royal Decree of 12/05/1992 included a validity term of 5 years for a Declaration of Compliance.

Food is a complex matrix and therefore the analysis of migrating substances in food may cause analytical difficulties. Therefore, test media (food simulants) are used which represent the major physic-chemical properties of foods. In certain cases, specific migration tests can be done directly in food, but overall migration can never be tested in food.

Dual use additives are additives which are listed in the Union list of authorized substances (European Regulation n° 10/2011 and amendments) for food contact plastics and which are also listed as food additives or flavourings in Regulations (EC) No 1333/200813 and (EC) No 1334/200814 and their implementing measures. So, dual use additives may be present both directly in the food as in its packaging.

Contact Us

Subscribe to our newsletter!

Get our monthly update on the packaging industry